Cobot Linear Track

FAQ's

Cobot is a shortened term for collaborative robot. This is a robot intended for use within a space that will be shared with humans, unlike the traditional robot which needs to be isolated from human contact for safety reasons.

The International Federation of Robotics defines four levels of collaboration between the human and cobot. This includes:

Coexistence - this is one of the most common forms of collaboration. Coexistence is where humans and robots can work alongside each other, without the need for a separating boundary; however they do not share the same workspace.

Sequential collaboration - this is another type of the most common forms of collaboration. During sequential collaboration, humans and robots share the same space without any form of boundary, however do not work simultaneously on the same part.

Cooperation - cooperation is less commonly seen, and is where humans and robots simultaneously work on the same part without separating boundaries.

Responsive collaboration - responsive collaborative, too, is less commonly used. This is where the robot responds in real time to the actions of a human.

Collaborative robots are used for repetitive tasks that need to be carried out consistently and accurately, for example, in the manufacturing industry where tightening screws can be repetitively done at the same tension.

The work of collaborative robots transcends just manufacturing, and can be seen in a range of industries. For instance, they are used in the medical field, from assisting or conducting surgical procedures to aiding physical rehabilitation. The research and education industry often rely on cobots, as well as some military applications and food processing services.

The entertainment industry has plenty of benefits from using cobots, for everything from creating TV and motion pictures, to entertainment ride systems.

There are plenty of benefits to using cobots in manufacturing, including:

- The ability to free up staff from monotonous, repetitive work – leading to a positive effect on employees and their mental health

- Increased productivity and ROI due to the speed and accuracy of cobots

- Consistent and accurate

- Low cost deployment

- Safer than industrial robots, thanks to both physical structure (such as lightweight materials and rounded edges) to programming (like sensors and limitations of speed and force)

- Versatile and can take on a variety of tasks in different departments

- Easy and quick programming and installation

Cobot Linear Tracks

The early origins of the collaborative robot, or cobot, can be traced back to the late 1960s; more recently, however, this technological phenomenon has become widespread thanks to the advantages it brings over traditional machines. Verifying this is the expected growth of the HRC (human robot collaboration) market - which is estimated to reach a value of £5.5 billion by 2027.

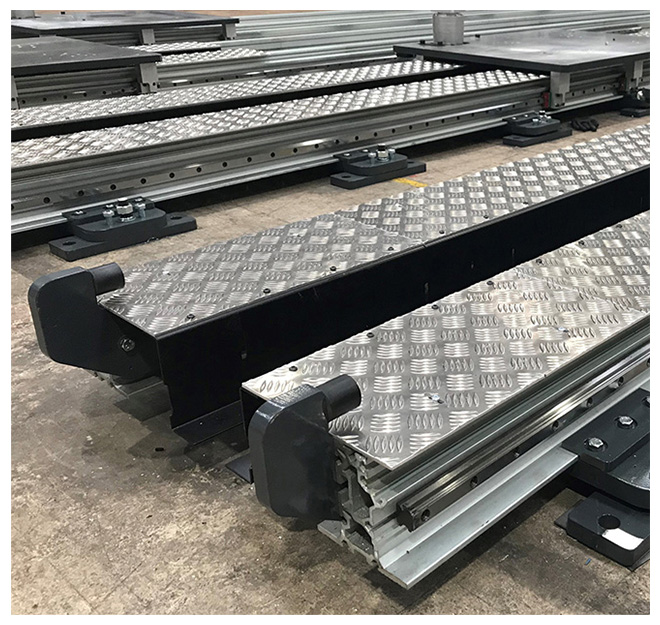

Understanding the growth and potential of the cobot market, Kyrus provides linear tracks suitable for the use of cobots. Our HiGlyde Mini linear track is a belt driven, single beam track, which can moreover be supplied with a drive module - perfect for hosting cobots.

So, what is the difference between cobots and robots?

Compared to the traditional robot, a cobot is built with safety in mind; they can be made smaller and less powerful than industrial robots and do not require the use of cages in order to prevent injuries caused by their movement. This means cobots can work alongside humans, which is great for factories that do not have the space to separate their human, and robotic, workers. Another main difference between cobots and robots is that cobots are often taught by example, rather than programming software. An operator can physically guide a cobot through its expected actions and movements, and the cobot will store this information and repeat it as needed. Where robots are built for power and speed, and can be programmed to perform a variety of tasks, cobots are slower and tend to be more specific in the tasks they undertake.

There is no definite answer in the choice between whether a robot or cobot is more suitable for your business, since both are beneficial in different ways; for this reason, Kyrus builds linear tracks suitable for both robots and cobots. Linear tracks can extend the work envelope of your cobot, an excellent way of increasing the ability of this smaller automation machine.

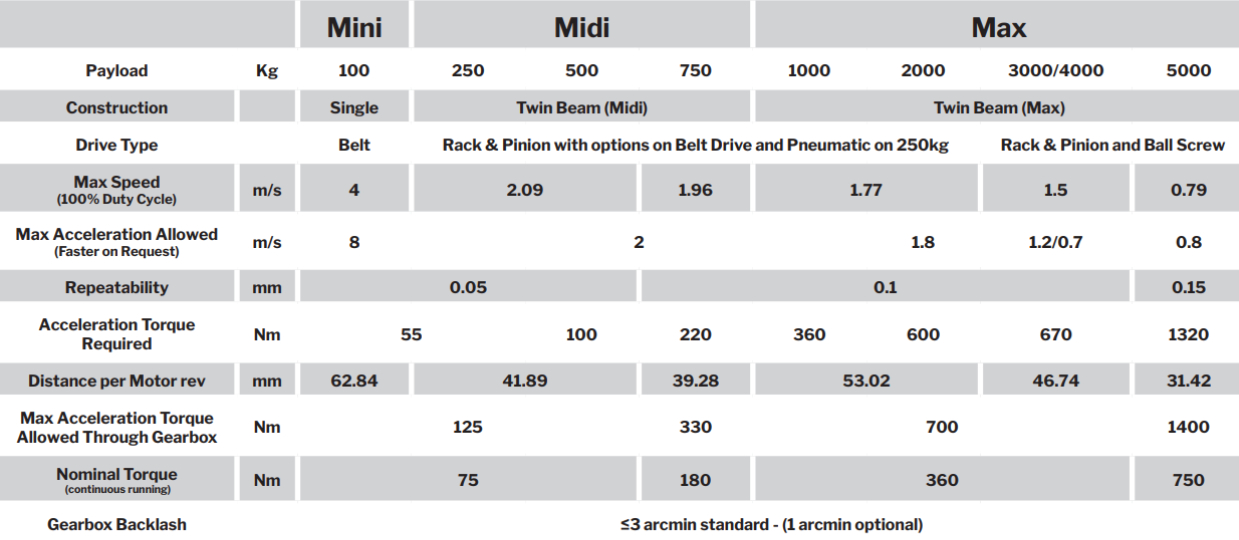

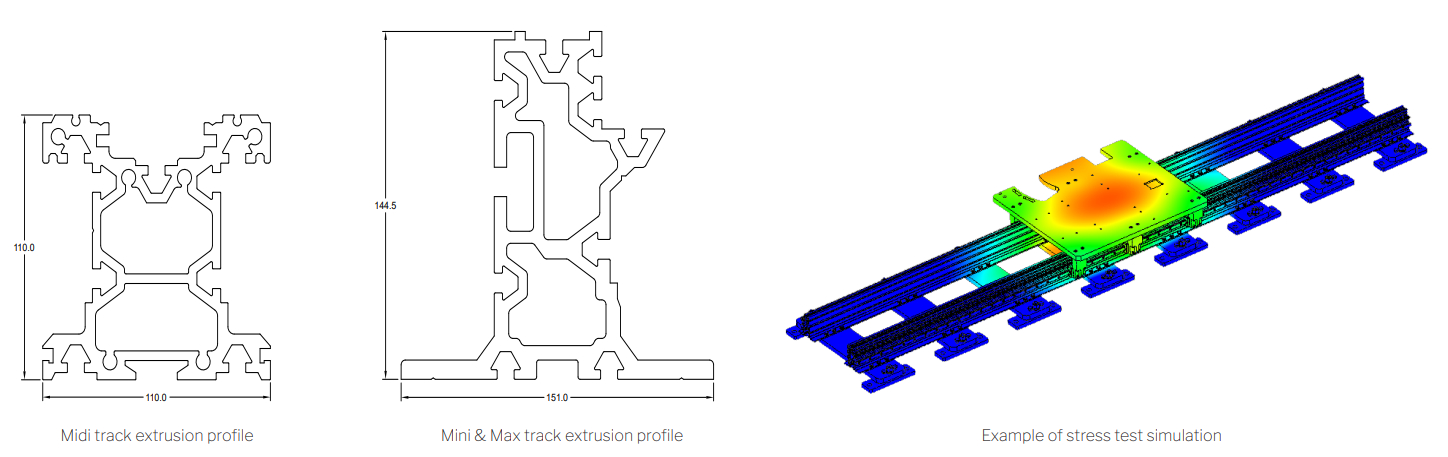

Techncial Data

Kyrus’ HiGlyde Mini can host your cobot with the following applications:

- Made using aluminium extrusions, unique to Kyrus

- Fully modular, and can be extended to any length

- Compatible with a range of drive options available, including rack and pinion and ball screw drives

- Able to be mounted to floor, wall, or ceiling

- Optional extras can be attached, such as additional carriages, robot risers and auto lubrication

- Low mounted precision linear guide rail for superior stability and rigidity with helical rack for flawless running

- System specific end stops adjustable feet with levelling screws and cross joining plates to match load requirements

- Anti slip chequer plate with central cable management system

- Integrated swing in gearbox housing allow for easy adjustments