End Effectors

| - | - | - |

|---|---|---|

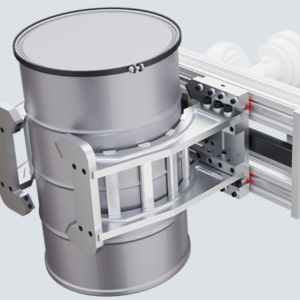

| The Max Grip | The Tri Grip | |

| Payload Capacity (kg) | 50-2000 | 20-1000 |

| Jaw Opening (mm) | 4000 | Additional increased jaw opening capabilities available |

| Construction | Single and Twin beams | Beams up to 5m | Designed to be self-centring | Supported by precision linear rails |

| Drive Type | Servo Driven | Servo Driven |

Kyrus has worked alongside a range of sectors to provide End Of Arm Tooling solutions for their automation needs, including, but not limited to:

- Robotics and automation

- Manufacturing

- Aerospace

- Automotive

- Food Industry

- Pharmaceuticals

- Packaging

- General Warehousing

End Effectors

An end effector is a robotic device used to hold, manipulate, or transport an object; they are also commonly referred to as end of arm tooling. Kyrus manufactures gripper end effectors to facilitate your automated possibilities.

Since there are so many different types of end effectors, they are typically characterised by being either mechanical (e.g., grippers) or electrical (e.g., welders). These end effectors can be attached to the robot or available as individual units. Examples of common types of end effectors include clamp tool, force-sensitive gripper, vacuum nozzle, and welding head. Many of these tools make use of custom electronics within them to give them unique functionality, and when choosing the right end effector for your robot there are several things to consider. Stroke, force of grip, weight, material, and variables such as repeatability all must be decided before selecting your end effector.

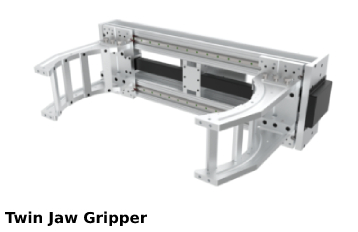

Kyrus has produced a series of modular servo robotic end effectors, known as ANT Grippers. Within this series there are two models available: the Tri-Grip and the Max Grip, designed with the latest CAD software for superior operation. Whether you utilise the twin jaw gripper for larger applications, or the tri-grip for handling smaller parts, Kyrus’ ANT Grippers help you get closer to your automated handling processes.

FAQ's

Literally speaking, end effectors will be installed at the end of a robotic arm - hence the name, end of arm tooling.

They are controlled by an operator to interact with their environment and are mainly found in manufacturing environments to create automotive, electronic, or consumer goods. They aid many operations, such as pick and place, palletising and stacking, surface finishing and packaging within these operations.

A gripper is the most common type of end effector, and it can be broken down into four main categories: vacuum, pneumatic, hydraulic, and servo-electric.

The vacuum gripper uses a powerful vacuum to hold the part against a high-friction pad. There are two types of vacuum grippers: single acting and double acting. Double-acting operates with compressed air, whilst single-acting relies on pulling air out of the gripping chamber with a piston or diaphragm. Vacuum grippers are best suited to delicate assemblies where small tolerances and a static hold strength are required.

Pneumatic grippers work well in assembly and material handling applications. They're also popular because the vacuum gripper's static pad is replaced by a pneumatic cylinder that can be easily adjusted to suit different part sizes and shapes.

Hydraulic grippers are best for applications where the part will be picked up or placed onto a conveyor. They work well on parts that vary greatly in size and shape because they can easily adjust to the part's contours without any special tooling. Hydraulic grippers can also handle parts like valves, gears, bearings, and other components that require more dexterity than simple grippers can provide.

Servo-electric grippers are similar to hydraulic grippers in that they're less expensive than vacuum or pneumatics. Servo-electric grippers are best suited to assembly applications that don't require sheet metal components or jobs that have consistent part geometries and sizes and where accuracy isn't as important as speed.

An end effector works through the power connections as described above, once attached to a robot’s wrist. The end effector’s programming then has to be integrated into the robot’s programming, in order for them to work collaboratively.