Guarding & Enclosures

Enquire Today

FAQ's

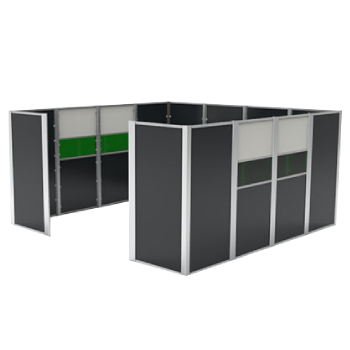

Enclosure guarding refers to creating a large barrier around a machine or automation cell, as opposed to around a specific hazard location, in order to prevent staff from injury from potential hazards. These types of enclosures can be entered for the operation or maintenance of the machinery contained within.

A guarding system is important to ensure that personnel are protected from any machine, process or function that could cause injury or death. Alongside this, however, guarding systems, such as enclosures, barriers, and guards, can also protect machinery and other inventory, support structures, and racking, since they prevent unauthorised access and encourage clear zoning of work procedures.

There are four main types of machine guarding, which aim to protect staff and machinery whilst limiting interruption of the everyday operation of the machine. Guards will vary depending on the requirements of the machine.

A barrier guard is a fixed guard; this is permanently secured to the machine at point of operation, to obstruct entry of employees' hands into the machine, and cannot be removed or adjusted.

An enclosure guard creates a barrier around the whole machine or its dangerous parts; this can typically be entered by authorised personnel to provide access to the machine for maintenance or other specific purposes, but otherwise completely blocks access to the machine or its hazardous parts.

A presence sensing guard operates differently from the above, and protects operators by stopping the machine if it registers that a body part is near a hazardous zone.

An interlocking guard, unlike the other types of guards, is not fixed. This type of guard may be unfastened for access or even completely detached - however, if this happens, the machine will automatically cease its operation in order to prevent injury or danger.

For robotic guarding, typical types of guarding methods include: enclosure guarding, fencing, or dividers, all of which provide a physical barrier between operator and robot. Shields can also be used for lower levels of guarding, such as to catch shards from cutting operations, or sparks from welding.

Guarding & Enclosures

Guarding is the preferred way of separating your dangerous machines from its operators; this is outlined by the UK Government, who first advise guarding, then a safe system (under specific circumstance) as a forefront step toward preventing workplace hazards when handling work equipment. Kyrus offers a range of machine guarding and robot enclosures for increasing the safety of your automation machinery and staff. Kyrus’ range of guarding and enclosures are fit to withstand the everyday activities faced by your manufacturing company, whilst maintaining a sleek and professional aesthetic.

Protective guards and enclosures are a legal obligation on some types of dangerous machinery. The HSE’s guarding standards state that, “access to dangerous parts should be prevented, or the movement of dangerous parts stopped before a person enters the danger zone”. The main areas of a machine most likely to cause injury are: point of operation, power transmission status, and moving parts.This is where all-encompassing guards and enclosures as provided by Kyrus can offer ultimate protection and peace of mind for your company.

In order to help you decide whether your automated machinery needs guarding, a PUWER assessment should be carried out.

PUWER is an acronym for the Provision of Use of Work Equipment Regulations 1998, which outlines the requirements for dangerous machinery parts. Machines commonly found in manufacturing which require guarding include: power presses, milling machines, and rolling forms.

Kyrus has worked with a range of sectors, helping:

- Robotics and automation

- Manufacturing

- Aerospace

- Automotive

- Food Industry

- Pharmaceuticals

- Packaging

- General Warehousing