Machine Guarding

Kyrus’ machine guarding is designed to give you peace of mind in your workplace. We’ve worked with a variety of sectors, including, but not limited to:

- Robotics and automation

- Manufacturing

- Aerospace

- Automotive

- Food Industry

- Pharmaceuticals

- Packaging

- General Warehousing

Machine safety is extremely important in the workplace, not just in the case of emergencies, but to prevent injuries on a day-to-day basis.

All employers must follow regulations governing machine safety in order to protect their employees and the machines they use. Kyrus provides machine guarding in order to give your workplace peace of mind when operating and working around all types of machinery.

The most common causes of injuries related to machinery often derive from a lack of training, incorrect operation of the machine, or lack of maintenance and inspection of the machine.

Machine safety procedures should be established within the workplace in order to prevent any hazards that may occur from moving parts, electric shock, hot surfaces, and more. A PUWER risk assessment and EN ISO 12100 can help you decipher the dangerous areas of your business and how you can establish some machine safety procedures.

There are multiple machine safety procedures - these can be relatively straightforward, such as ensuring workers wear personal protective equipment, for example gloves and boots, and installing warning signs on machines; they can also be more complex, and need professional installation, like safety relays or fencing.

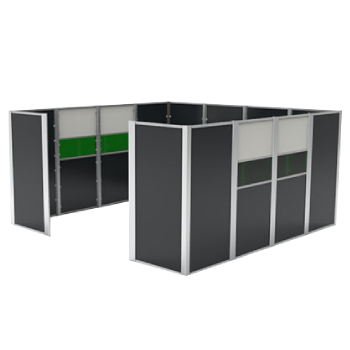

The best way of safeguarding your staff and machinery from hazard is to place a guard around, or on, the dangerous parts of your machinery. Kyrus provides machinery guards equipped to withstand the everyday conditions of your workplace, whilst continuing to perform under emergency situations.

FAQ's

The types of machine guarding include fixed, interlocking, adjustable, and self-adjusting. Each has benefits and drawbacks in terms of providing protection to the user and maintaining proper worker safety procedures.

Fixed: This type provides a permanent barrier between the user and the dangerous parts or moving components on a machine. It is typically mounted on top of the machine, making it difficult to bypass.

Interlocking: This type of guarding is similar to fixed, in that it is mounted on top of the machine and provides a barrier between the operator and the dangerous parts of the machine. A major difference with this type is that it also prevents users from starting or powering up equipment if they bypass or remove part of the guarding. This type of machine guarding is most suitable for machinery where the operator will be in close proximity to moving parts or hazardous equipment, such as spinning blades on a table saw.

Adjustable: This type of machine guard is typically used on industrial machines, like band saws and lathes, which are frequently adjusted for different tasks. The guard is easily removed and replaced with a different type of guard, depending on the task being performed. This type of machine guarding is essentially a safety cage that provides a barrier between the user and dangerous parts while also protecting them from flying chips or debris.

Self-adjusting: This type of machine safety device includes fuses that trip if a user attempts to bypass the machine guarding. These types of guards are designed specifically for special-purpose machinery, such as food slicers and press brakes. It can be used on other machines, but typically not in heavy production settings where users may need to frequently clear debris or perform other tasks while using the equipment.

PUWER is the Provision and Use of Work Equipment Regulations 1998 and requires users of work equipment to carry out regular risk assessments which are documented and kept on file.

Put simply this is the machine safety “bible” and contains all of the important definitions along with basic rules for selection of safety measures and detailed instructions for risk assessment.

If there is a potential hazard from a moving part, hot surface, or electrical discharge by contact then people should never be allowed to come into contact with the hazard involuntarily.