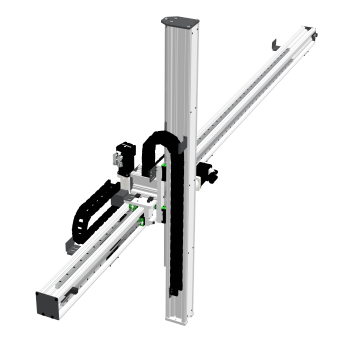

2 Axis Gantry

FAQs

A two axis Gantry system is a framework that allows for movement across an X, Z coordinate system. The X axis represents the ability to move lengthwise, whilst Z refers to up and down movement.

Two axis gantry systems are great for high speed and capacity activities, and are moreover versatile and adaptable, meaning they can be applied to a number of operations. These include, but are not limited to, pick and place, stacking, palletising, assembly and manufacturing.

The number of axes your robot will need will depend upon the type of application you are automating along with the complexity of the process. The more axes your robot has, the greater its mobility in a number of coordinates.

Whilst utilising a full six-axis machine will enable your robot to perform to its highest capability, with the most complex movements, you should only incorporate the number of axes you need into the design of your robot. More axes will typically come with a higher price tag, alongside an increased risk of hazards, and more axes to maintain and repair if your robot experiences downtime.

If you are unsure, it is best to discuss your requirements with the robot manufacturer.

2 Axis Gantry System

- Made from unique aluminium extrusions

- Fully modular and easily extendable to any length

- A range of drive options, including rack and pinion and ball screw drives

- Able to be mounted to floor, wall, or ceiling

- Compatible with optional extras, such as additional carriages, robot risers and auto lubrication

- Low mounted precision linear guide rail for superior stability and rigidity with helical rack for smooth running

- System specific end stops adjustable feet with levelling screws and cross joining plates to match load requirements

- Anti slip chequer plate with central cable management system

- Integrated swing in gearbox housing allow for easy adjustments

Kyrus designs and manufactures cartesian gantry systems fit for all types of applications; our two axis gantry ensures precision and smooth operation, with aluminium extrusions offering strength to support payloads of up to 250kg.

The main advantage of using a two axis gantry system is the reduced number of axes in comparison to a three axis or higher gantry.

Two axis systems are simpler which means they require less maintenance and have inherent safety features built in because there are no rotating parts. This makes them well suited for high speed, accuracy demanding applications where the energy expenditure is the primary factor. These machines can have very high accelerations because there are less degrees for the machine to travel and thus there is less time wasted going from one axis to another. Two axis gantries are also space efficient because they can be mounted in confined spaces, closer to each other than a three axis system would allow.

Like most gantry systems, the two axis machine consists of a top frame, an X-axis slide (Y car) and a Z-axis slide (X car). The X car moves on the Y slide, while the Y moves on the X. The Y car is mounted on the base of the gantry with vertical support while the X car is mounted on bearings that run on both the Y and Z slides. This allows more of a compact machine with less moving parts than a three-axis gantry system.

Kyrus’ two-axis gantry is flexible in its configuration, whilst not compromising on speed, accuracy, and streamlined, low friction motion. Kyrus works closely with our customers to ensure their needs are met when designing and manufacturing your two-axis gantry system; we offer differing levels of support depending on your needs.

The two-axis gantry is designed for heavy-duty industrial use, with more axes available if you so require. Available for worldwide shipping, your gantry system will be delivered in modular form for easy construction. The expected lead time for our gantry systems is 6-8 weeks, depending on the level of customisation.