Factory Automation: Machine Guarding Requirements

Machine guarding (otherwise known as machine enclosures) is a preventative safety feature

Guarding provides a risk reduction for both protection against un-intended access and against ejected parts and substances. Guarding can also give protection against other hazards such as noise, fumes, radiation, and other hazards.

Enquire Today

What are the Machine Guarding requirements for factory automation?

To ensure the safety of workers, OSHA (US Gov official body for workplace safety and wellbeing) has six machine guarding requirements, which all safeguards should meet.

1. Prevent Contact

2. Be Secure

All parts of a worker’s body should be prevented by the machine guards. This prevents them from coming into contact with dangerous moving parts

The guarding cannot be easily removed or tampered with by workers. To withstand all conditions, it should be made out of durable materials. If possible, the guarding should be secured to the machine, if not an attachment should be used.

3. Protect From Falling Objects

4. Create No New Hazards

If objects fall into moving machinery parts, guarding can be put into place to stop this from happening. This results in your machinery not being damaged and avoiding unplanned downtime.

Safeguards should have no sharp edges as this can cause injuries.

5. Create No Interference

6. Allow Safe Lubrication

Workers should still be able to complete their tasks as normal and comfortably. If this is not the case then the safeguards may be disregarded. The safeguards should enhance workers efficiency as they shouldn’t be worried about sustaining any injuries

If it is possible, maintenance workers should look to locate oil reservoirs outside the guard which should lead to the lubrication point. Thus, reducing the need for workers to enter the hazardous area.

Here at Kyrus all of our machine guards comply with the OSHA machine guarding requirements as well as ISO14120:2015 - Allowing you peace of mind when you buy our machine guards, knowing that it can protect your workforce.

Different types of machine guarding and enclosures:

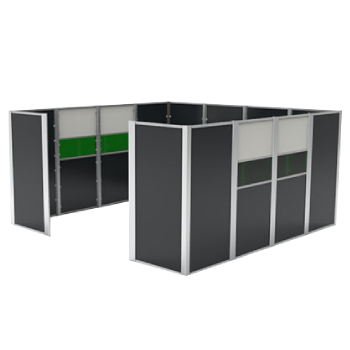

Robot Enclosures

Machine Guards

To maximise protection to the workforce, the entire robot and associated equipment can be placed in a robot enclosure. This helps to prevent injuries, damage and limiting access to workers. At Kyrus we can build robot enclosures to meet your specifications. We have a range of standard options which can be tailored to suit your requirements - The colour of the panels can be changed to fit your branding, doors with integrated interlocks can be provided, we have a host of different window / mesh options, but most importantly we can design your guarding project!

Laser Welding Enclosure

Here at Kyrus, we offer laser welding enclosures (passive protection). What are laser welding enclosures? Handheld laser welding takes place within an enclosed area. Only when the door is shut will the laser activation begin. This helps prevent harmful light causing damage to your workers eyes and skin and helps contain / extract any harmful fumes generated by the laser welding or cleaning process.

We can also combine our knowledge of robot enclosures and laser welding, to provide laser safe enclosures for robotic laser welding systems.

There are several types of machine guards for different purposes, with some being changeable and some being permanent.

Acting as a protective barrier between the workers and the machinery, fixed machine guards are permanent. This means it is difficult to remove and change. Similarly, to fixed machines, interlocking machine guards act as a barrier. If part of the guarding is removed, the machinery may not power up. Machines can do different tasks which have varying degrees of risk, adjustable machine guards cater for this. As the name suggests adjustable machine guards can be removed and replaced with a different type of guard based on the machine’s task.