Robot Guarding: Why it’s Required for Health & Safety of Your Automation Solution

Robot Guarding & Robot Safety

Robotic guarding (sometimes known as robot cell perimeter guarding), is fence which is placed around the hazardous areas of manufacturing/ engineering equipment. It prevents your employees from coming into collision with the industrial robot system which may be working at high speed and is otherwise unaware of the presence of humans. Robot cell perimeter guarding is one of the most important safeguards to prevent personnel in the vicinity from coming into contact with the robot, its end of arm tooling or the robot payload. It should also protect employees from any hazards, such as chips or sparks, unintentionally exiting the machinery.

PUWER (provision and use of work equipment regulations), helps determine whether a piece of machinery needs robotic guarding.

Enquire Today

Why is robot guarding required for the health and safety of your work force?

Why is robotic guarding required for robot health and safety?

Automation health and safety needs to be considered and in place in order for work forces to be protected, especially in the manufacturing sector, as eight in ten workplace deaths involve mechanical equipment.

The use of any machinery has a degree of risk, especially for the workforce. Operation, maintenance and lubrication of any machinery all have associated hazards. To prevent injuries, machine guarding can be installed to prevent injuries connected with moving parts of machinery.

It is important to carry out comprehensive risk assessments for automation components. This should be done on each individual piece of machinery or robot cell. In doing so it identifies any hazards associated with a particular machine. Once it has been fully assessed, suitable automation guarding can be put in place.

What do Robot Safety Regulations say?

There are legal procedures and regulations which need to be followed to minimise the risks associated with machinery. According to the ISO standard - “The primary purpose of this International Standard is to provide designers with an overall framework and guidance for decisions during the development of machinery to enable them to design machines that are safe for their intended use”.

It must be noted that failure to adhere to regulations, could result in legal actions, especially in the event of employee injuries.

As mentioned above robotic guarding can prevent injuries and fatalities caused by automation components. The use of robotic guarding encloses the dangerous parts.

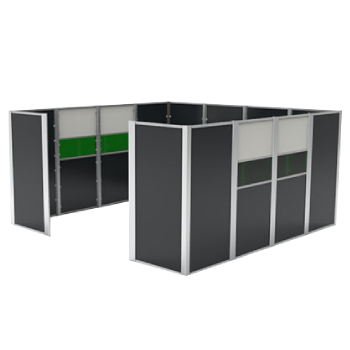

Here at Kyrus we offer machine guarding and robot enclosures. A Robot enclosure will protect a specific robot where as robot cell perimeter guarding may be used to create a barrier around a number of robots and other pieces of equipment. Both have the same purpose; to protect employees from workplace injuries and deaths.

What is PUWER?

PUWER stands for The Provision and Use of Work Equipment Regulations. The purpose of this regulation is to protect workers from unsafe machinery and other work equipment. Work equipment should be safe to use and be in a safe condition to prevent workplace injuries.

As stated above, under PUWER, risk assessments need to be undertaken on all high-risk automation components. It should be noted that the risk assessments should be undertaken by experienced staff that have received training and have knowledge on how to assess machinery. Therefore, allowing employers to make any necessary changes to minimise workplace injuries.

How could opting for the right required parts for your robotic guarding fit in with the required health and safety of your automation solution? Click here to see why Kyrus is number 1 for required automation guarding parts.